When choosing between the different building materials like brick, Hebel, cladding or otherwise its important to know the pro’s and con’s of each as well as the costs involved. You might want a rendered look which is means you have other limited options.

For the purpose of this post double brick walls are excluded.

Theres a pretty good site that explains the differences in more detail from Forsyth

What the House Looks Like

Brick Veneer / Facebrick

Brick veneer is where you have a single brick course on the outside and a timber/steel frame on the inside. Bricks here are more expensive than common bricks. They can have a colour over it however if the brick chips which is often the case you will notice the reddish colour behind them.

Laying facebrick also requires the brick layer to be more careful about laying it straight and neat. Once the bricks are laid they will need to be cleaned, normally with an acid wash.

Austral and PGH are the most used by the builders in NSW and they normally have contracts with them with discounted pricing for certain ranges. They have more expensive ranges in bricks that can add a few thousand if you decide to go with them. As an example, through Austral most builders will include the Wilderness range which includes Blue Gum and at the time of writing this costs $1952 per 1000 bricks however they would be discounted to around $1000 per 1000. If you wanted Austral San Selmo reclaimed these go for $3000 per 1000 bricks. This can cost you up to about $5-45k extra for a double storey depending on how much of it is used. The discounts for non-standard bricks is much less so you shouldn’t compare the retail pricing directly. If you call up Austral or PGH and ask for the price of around 20k bricks you will get a better idea of what a builder pays for it.

You get Extruded bricks which have holes in them that makes it cheaper to make and lighter to use and then there is Dry Pressed bricks which is a solid brick that is a more premium brick.

When choosing a brick colour, extruded bricks can be coated in a coating (like a paint) or glaze. Over time the bricks can chip and you see the red base colour underneath so be aware of this.

Render

There are a number of different options for having a rendered look which arent too different in cost in some cases. Other than the ones listed below there are a number of other good alternatives that should be considered too if you want a rendered look.

Consider the maintenance that comes with a rendered house. A face brick house for instance doesn’t require painting, just possibly cleaning. Render can stain over time, especially one that isn’t a smooth finish or ones that don’t have cappings.

Rendered Bricks

Common extruded bricks would be used along with acrylic render used afterwards. Common bricks at the time of writing from Austral would cost $1598 and render on the entire house would quite easily add another $25k.

They are cheaper to lay than face brick as the render will hide imperfections however the render cost makes it significantly more than facebrick as an option.

Hebel PowerPanel

Hebel is a lightweight aerated concrete that has been around for over 50 years and was invented in Germany. Its quick to put up and is a cheaper alternative to rendered brick. Hebel is often a like for like cost comparison to brick veneer and builders will often allow you to choose between either with no cost difference.

Hebel is also used as a lightweight material for first floors and is more economical to use where the walls don’t line up underneath. It would be an alternative to cladding however it is a bit more expensive. It is still cheaper than having bricks as they would likely require steel supports underneath.

Hebel will have an acrylic render applied after its installed.

The common issues people raise about Hebel is that it can chip easily (think of a mower bumping into it), crack (can be due to incorrect installation) and harder to hang heavy items on it however there are ways this is achieved through specific screws and other techniques.

There are thermal and soundproof/acoustic benefits that are described later in this post.

EPS (Expanded Polystyrene)

Similar to Hebel but made of a type of polystyrene its a lightweight material that has acrylic render added to it after installation.

EPS is banned from use in certain types of buildings in Victoria and it may impact your house insurance costs. Its worth investigating this further with your builder to find out if this impacts your build. It can be rated up to BAL29 for certain products. It is also less prone to cracking as polystyrene doesn’t expand

Blueboard / James Hardie Fine Texture Cladding

This is a fibre cement board which doesnt offer the same structure, thermal and sound benefits as other materials. This is pre-sealed and ready to paint so render isn’t required to go over it saving time and money over Hebel Power Panels and EPS.

Cladding

Cladding products don’t require rendering and just need to be painted. They can be installed quickly and with little mess compared to bricks or other products.

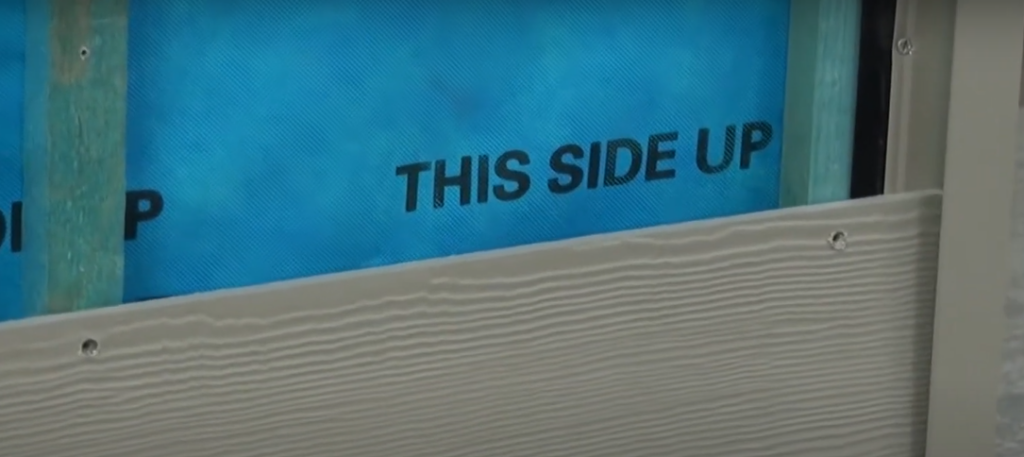

They are however lightweight materials and don’t provide much in terms of thermal or acoustic performance. A house wrap is required behind them which protects against moisture, dust and drafts. It isn’t waterproof and even the cladding itself allows moisture to form behind it however its installed against battons which allow the water to drain behind them onto the ground or a channel at the bottom.

James Hardie Scyon

These are a fibre cement board that are installed by overlapping each other horizontally. They come in various widths.

James Hardie Matrix

Matrix cladding also comes in various sizes. Its very different to something like Scyon as the panels don’t overlap which makes water ingress much easier but expected. They are glued on a metal plate and nailed to the battens. James Hardie joint sealant is used to seal the gaps.

Thermal and Acoustic Benefits

Hebel offers almost 3x the thermal benefits of brick whereas cladding on a house provides almost no thermal insulation. It releases heat more quickly compared to bricks which is beneficial in a warmer environment.

A house wrap (sarking) provides minimal thermal benefits directly and is used more for moisture management (it’s not waterproof), drafts, and for fire prone areas (BAL). By limiting drafts it helps as a barrier to other thermally efficient materials. Think of it like an umbrella during strong winds. On a cold day, by reducing the wind hitting you, the temperate appears warmer.

| Material | R rating (Thermal) | Rw (Acoustic) | Price (p/m2) | Weight (p/m2) |

|---|---|---|---|---|

| NRG Greenboard – 75mm | R1.95 (direct fix) R2.65 (batten cavity) | 37 Rw (system incl. frame + 10mm gyprock) | $16-20 | – |

| NRG Greenboard – 100mm | R2.60 (direct fix) R3.31 (batten cavity) | 39 Rw (system incl. frame + 10mm gyprock) | $19-25 | 1.79 kg |

| Hebel PowerPanelXL – 75mm | R0.52 | 34 Rw (panel only) | $50-60 | 51.39 kg |

| Hebel PowerPanel – 100mm |

The CSR redbook on pg 198 has more details about Hebel being installed in a timber wall frame with insulation.

Maintenance

The choice of material for a wall will result in different types of maintenance required to keep it clean and looking new and watertight.

| Material | Pros | Cons |

|---|---|---|

| Bricks | ✅ No repainting and minimal maintenance to retain the look. | ❌ a common area of discolouration is on parapet walls where a capping doesn’t drain water away from it and it can result it streaks forming on it. ❌ If the colour of the brick is painted on, which is on the entry level bricks then when there are chips to the bricks the brown colour will be visible. |

| Render | ✅A good paint can retain the colour for a long time. Using acrylic render will help reduce cracks | ❌Will need to be repainted every few years as the paint discolours or is stained ❌Cracks would need to be patched ❌Patching can be costly. EPS is easier and cheaper to patch vs Hebel |

| Cladding | ✅With some cladding systems it can be easy to replace broken panels | ❌Will need to be repainted every few years as the paint discolours or is stained. ❌Gaps can open due to thermal expansion and require caulking every few years in some areas |